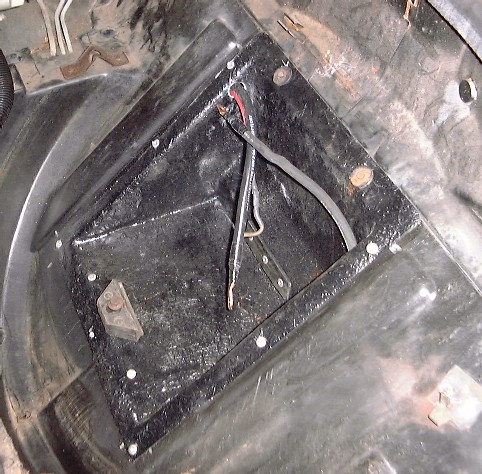

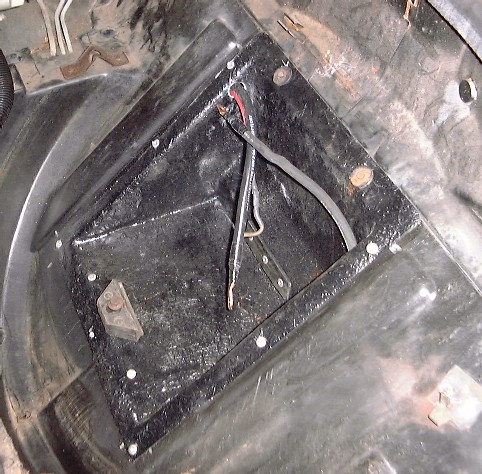

Battery is getting relocated to the front using one of norm's kits. I modified the tray by adding provisions for "tying down" the battery in case no spare tire is going to be present (stock spare won't work with the 12" brake upgrade that is going on this car).

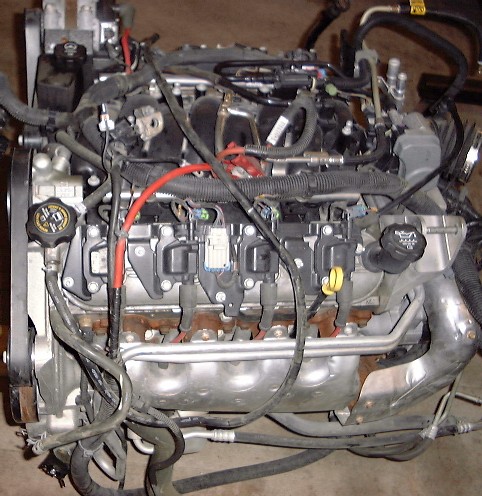

Got started on the exhaust system and built it as far as to the cats. Will finish it up once the engine goes back in for the last time.

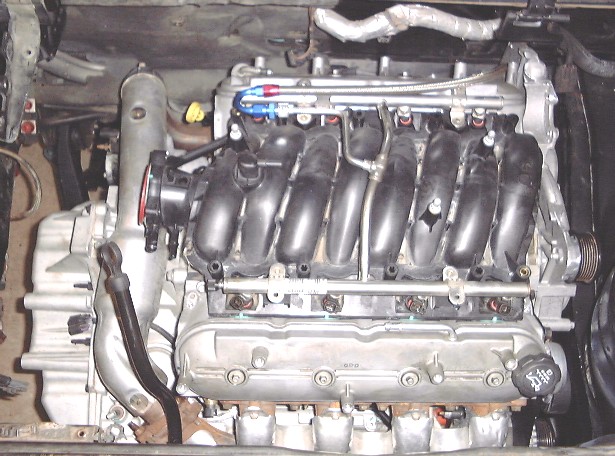

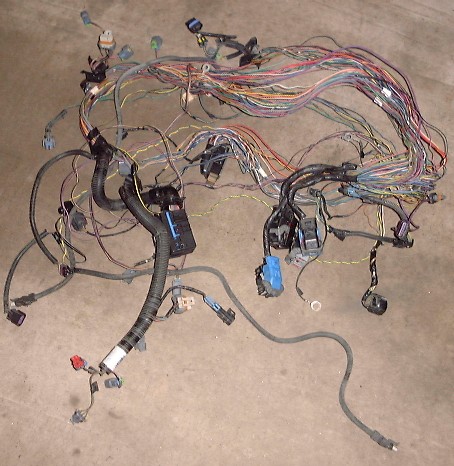

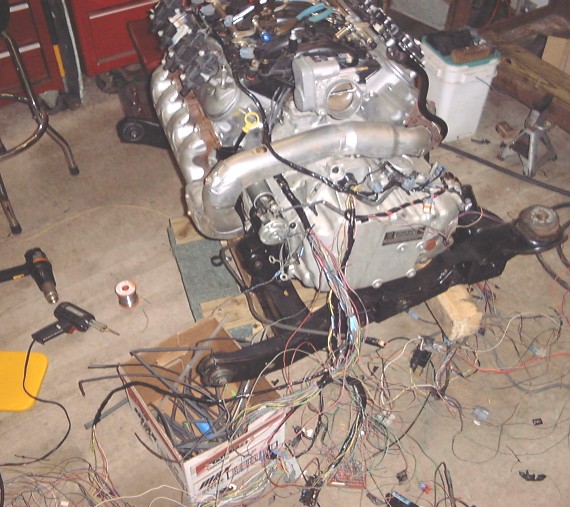

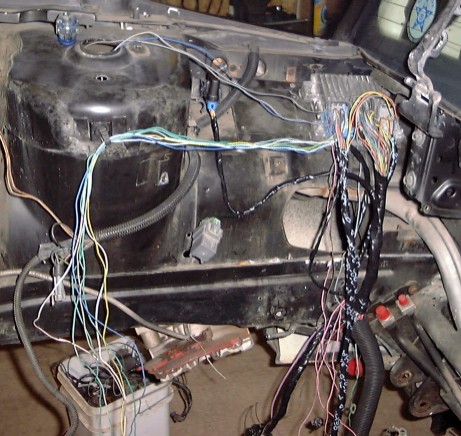

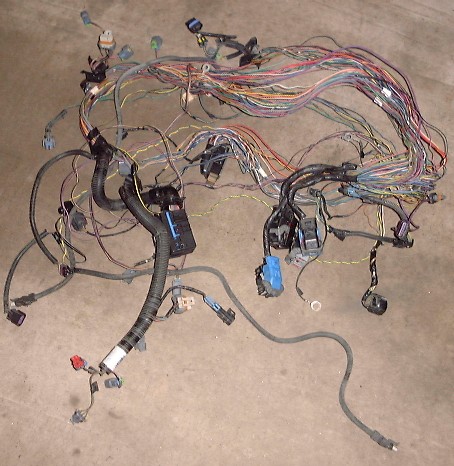

Below is a picture of the LS4 engine and transmission wiring harness with most of the loom removed. I took a few measurements before I removed the engine/trans from the car this last time so I can get as much rewiring done as possible with the engine out. Saves me from having to lean over into the engine compartment as much.

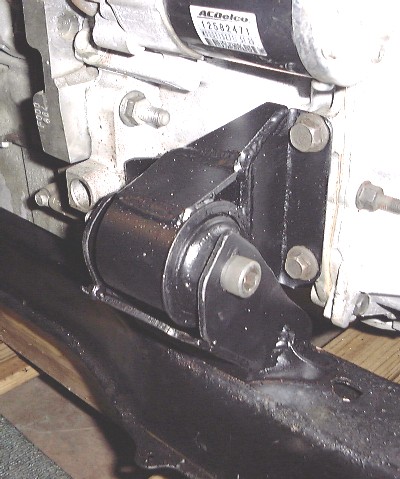

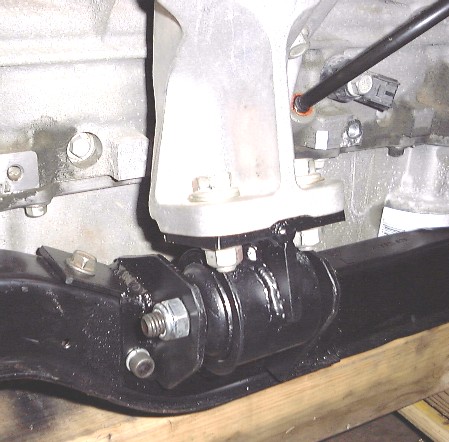

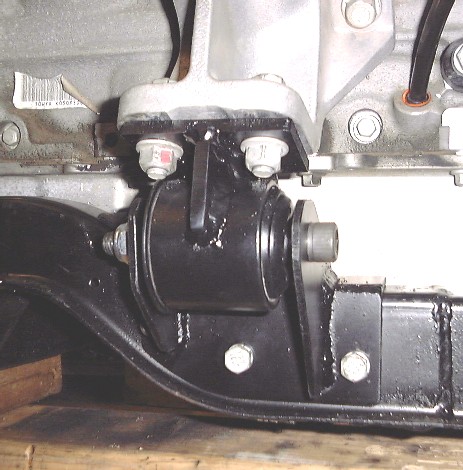

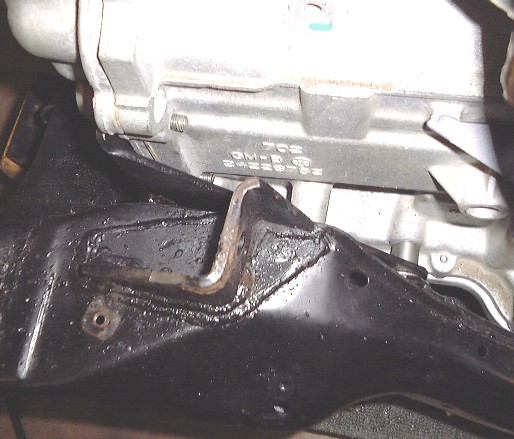

For ECM and TCM mounting I recycled some of the fiberglass front spare tire well I had to cut out for the battery box. The cases of the ECM and TCM should never be mounted to a metal surface that is grounded to the chassis. The reason why is because if the ground strap ever became severed from the engine to the chassis, or from the engine to the battery (but still connected from battery to chassis); high current could go thru the computers and damage them. GM keeps the cases to their computers isolated from chassis ground for this reason.

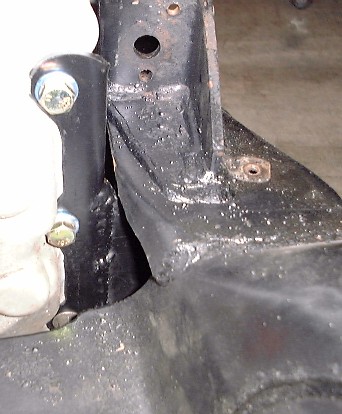

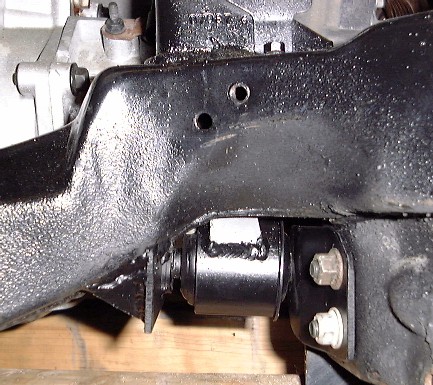

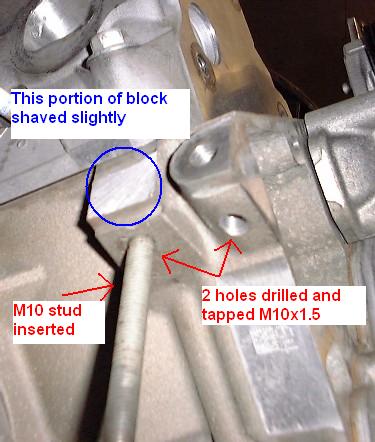

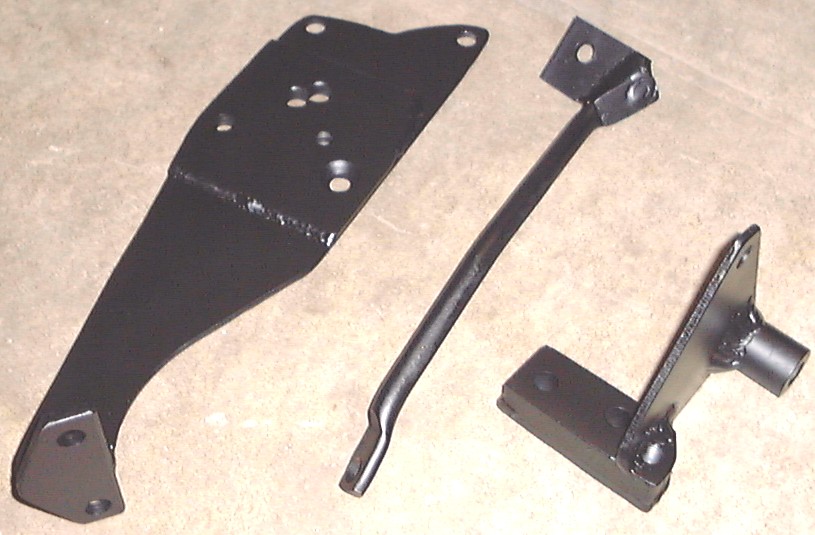

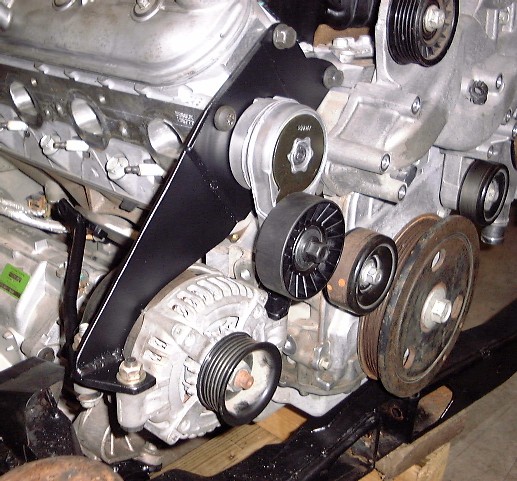

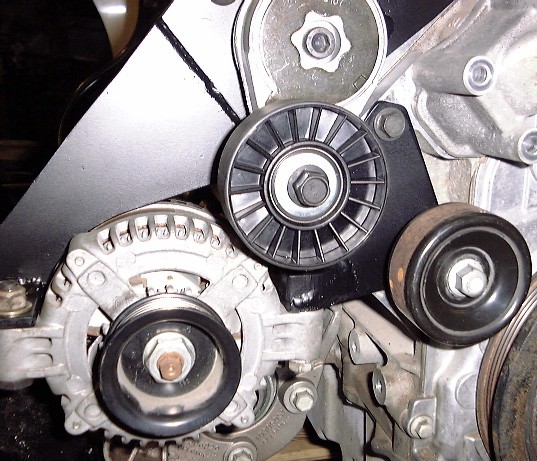

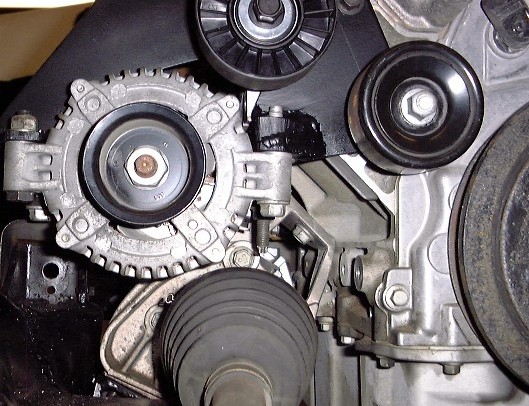

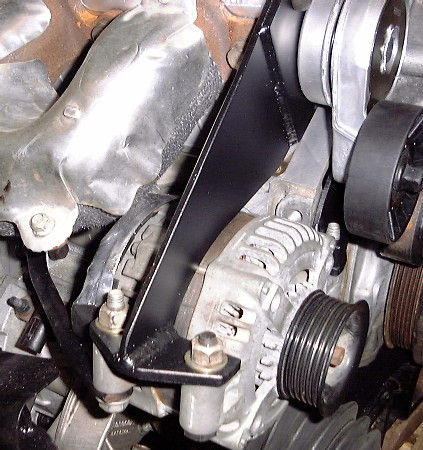

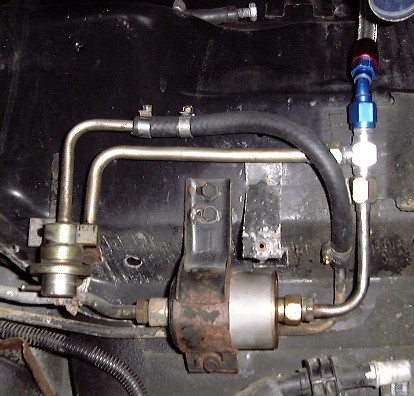

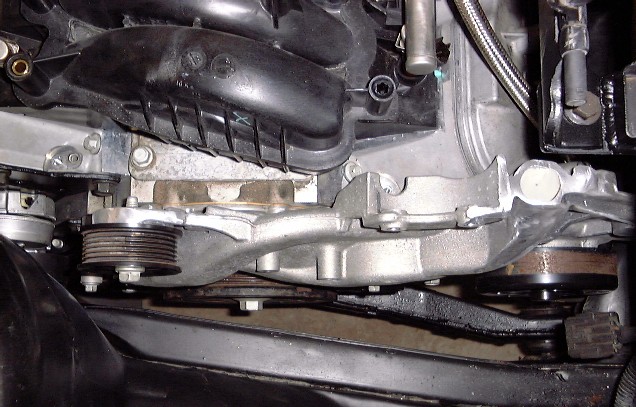

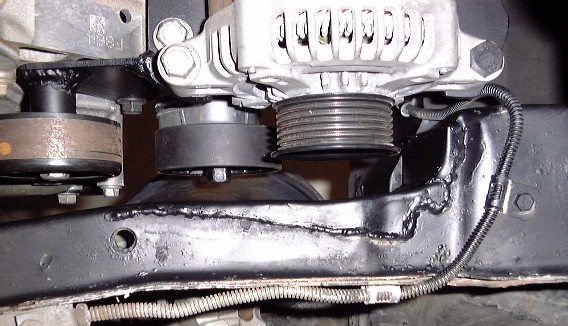

Also received the powdercoated suspension pieces from blkcofy and they look great. Got the new ball joints pressed into the front lower control arms tonight. I also got some fittings made for the modified front engine/water pump cover. Will get those welded on next week so I can get that put back on the engine and finalize my serp belt routing. Not pictured is the wiring I have already completed for positive and ground supply from the battery to chassis, engine, and alternator. The battery relocation kit comes with 4ga cable to run from the pos battery term to the starter; but for this swap I elected to upgrade this to 2ga because of the V8. I did use the 4ga cable to connect the starter to the Fiero's original power distribution block. I also pulled the clutch line, shifter, and shift/throttle cables from the car. Installed the auto trans cooler lines and I am working on mounting the fly-by-wire gas pedal assembly.

Something else noteworthy that I haven't spoken of yet is a tale about the ECM that came with this engine. This tale actually encompasses a couple of weeks that it took me to get where I am now. The ECM that came with this engine did come out of the same car the engine came out of. But what wasn't known at the time was that the ECM had been custom programmed by a company that I prefer not to name here. I didn't discover this until I got my bench harness built a couple of weeks ago and tried to read its programming using my HP Tuners tuning software. In short, the HP Tuners software wouldn't read the ECM at all and gave me an error indicating the security codes in the ECM had been changed (locked). HP Tuners customer support informed me that this ECM was probably not going to be usable unless I could hunt down the person/company that reprogrammed it and get them to unlock it. Well while I was waiting on getting in contact with the reprogrammer, I took the ECM to the dealer to see if they could force a reflash using SPS pass-thru programming. Well that ended up not working because of the software lock in the ECM.

After about a week I was put in touch with the original programmer and he informed me that the software he used to reprogram this particular ECM was in BETA TEST back when it was done. He also said he no longer had the beta software and basically the ECM I had was worthless (IE he couldn't even reprogram it if he wanted to). So, in short, I had to order a replacement ECM which I did get ahold of one for a very fair price. So hopefully in the next few days I will get the opportunity to get into the dealer and get the correct stock programming and VIN put onto this replacement ECM so I can start working on the custom program that will be used in this swap.

At this point there are a lot of different things I am working on at the same time. So updates and pics may be slow in coming.

-ryan