Page 5 of 25

Posted: Sun Oct 30, 2005 10:13 am

by Kohburn

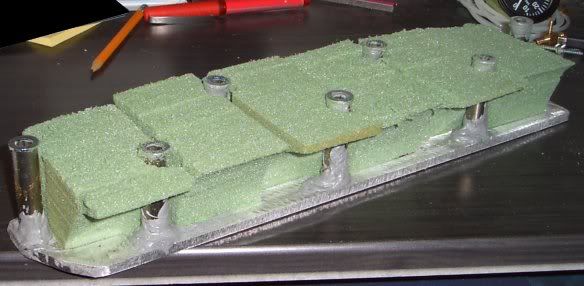

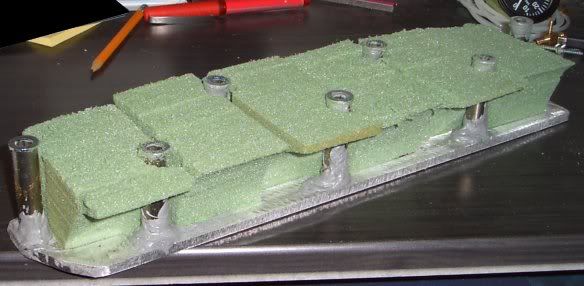

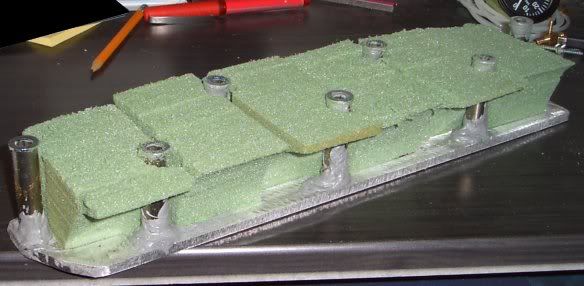

may as well add a teaser pic of some of the progress from friday - no thats not jb weld - however humorous that would actually be.. perhaps i should build it out of dimes - but thats kinda expensive for something this size.

you can't quite tell but there are 1/8" dividers between each runner - the top is being added today all the way up to the TB.. once tis all solidly glued together then the epoxy work will begin

Posted: Sun Oct 30, 2005 12:11 pm

by Shaun41178(2)

I see what you are doing there. Not bad. Keep us updated.

Posted: Sun Oct 30, 2005 8:35 pm

by Kohburn

lastest update of its form

from the TB it flares out

the dip int he center is soirt of like air flow control but is probably mostly cosmetic - i'm not sure if that is how i am going to leave it just yet - but it gives the basic shape for now

Posted: Sun Oct 30, 2005 9:06 pm

by The Dark Side of Will

Blue Shift wrote:What is the Great Stuff? Some sorta Urethane? I always thought it cured by some reaction not unlike polyester resin does.

Perhaps its just a plastic dissolved into a solvent with a blowing agent/propellant mixed in? If that's the case, yea it's going to need to evaporate all the solvent out. It probably also means that you could melt it with the correct solvent, as well.

Yeah, "great stuff" is expanding polyurethane foam sprayed out of a can.

When first introduced, it was called single expanding, double expanding or triple expanding. Then the marketing people noticed it was selling well and dumbed it down to "windows and doorframes", "gap and crack filler" and "big gap filler". Typical of baboons in marketing...

Once polyurethane is set, basically nothing will touch it. It doesn't have to be dissolved in a solvent. It's a reaction that cures when sprayed. As I've said, I've never had issues with it not curing completely.

Posted: Mon Oct 31, 2005 2:27 pm

by Oversteer

I am kinda doing the same thing as you, but I am using SM insulation rather than the spray foam. It forms pretty well with the dremel on low speeds, but I think I will need to cover it in something to make it perfect. Are you going to smooth yours out with something or just apply your material on the foam?

Posted: Mon Oct 31, 2005 2:31 pm

by Kohburn

Oversteer wrote:I am kinda doing the same thing as you, but I am using SM insulation rather than the spray foam. It forms pretty well with the dremel on low speeds, but I think I will need to cover it in something to make it perfect. Are you going to smooth yours out with something or just apply your material on the foam?

current plan is to cover the foam with silicon caulk to smooth it and also as a release agent for the epoxy (and i ditched the expanding foam a while ago)

Posted: Mon Oct 31, 2005 2:32 pm

by Oversteer

Can you sand the silicon?

Posted: Mon Oct 31, 2005 2:34 pm

by Kohburn

Oversteer wrote:Can you sand the silicon?

no thats post sanding - you spread it on smooth as it is a thin paste to start with and will take about an hour to dry

Posted: Mon Oct 31, 2005 2:38 pm

by Oversteer

I guess the resin won't stick to the silicone?

I gotta thank you for doing this first, you've paved the way for my future failed project hahaha.

Posted: Mon Oct 31, 2005 2:43 pm

by Kohburn

Oversteer wrote:I guess the resin won't stick to the silicone?

I gotta thank you for doing this first, you've paved the way for my future failed project hahaha.

generally speaking epoxy doesn't stick to rubber - there are exceptions and sometimes there are primers to make epoxy stick to rubber.

but silicon and latex have worked well in the past as mold making compounds for me

Posted: Mon Oct 31, 2005 3:10 pm

by Oversteer

How do you secure the plenum and runners to the flange?

Posted: Mon Oct 31, 2005 3:16 pm

by Kohburn

Oversteer wrote:How do you secure the plenum and runners to the flange?

the aluminum surface is prepped and will be more than happy to bond to the epoxy - after all it is aluminum filled epoxy

Posted: Mon Oct 31, 2005 3:17 pm

by Oversteer

Now if I ended up using Carbon Fibre, would it also work?

How much did your material cost? I am still unsure of what I am going to use.

Posted: Mon Oct 31, 2005 3:19 pm

by Kohburn

Oversteer wrote:Now if I ended up using Carbon Fibre, would it also work?

How much did your material cost? I am still unsure of what I am going to use.

foam blocks were about 5$

aluminum filled epoxy thats good to 500* was 45$ for a pint

aluminum was free out of the scrap bin at work

and the steel bolt risers (spacers) were about 3$ from ace hardware

Posted: Mon Oct 31, 2005 3:20 pm

by Oversteer

Are you just using the resin? No fibre material?

Posted: Mon Oct 31, 2005 3:38 pm

by Kohburn

Oversteer wrote:Are you just using the resin? No fibre material?

yeah I'm using some fiberglass cloth in mine but the resin itself has a 10,000psi rating

when its all done i may make a ceramic mold of it and cast aluminum copies

Posted: Mon Oct 31, 2005 3:40 pm

by donk_316

Kohburn wrote:Oversteer wrote:Are you just using the resin? No fibre material?

yeah I'm using some fiberglass cloth in mine but the resin itself has a 10,000psi rating

when its all done i may make a ceramic mold of it and cast aluminum copies

Do it. I wanna run one.

Posted: Mon Oct 31, 2005 3:43 pm

by Oversteer

Must be nice having the skills and the equipment to do things like this. For me, most of my skills are focused around the work I do, but with consulting you spend so much time talking a planning things, that actually getting down and doing them is a whole different ball game. Your project has given me the courage to actually start my project.

I decided to start with a short runner intake, and see how that goes, if it works out, I can modify the intake I am making to accept the longer runners with the runner control modules I got off the SHO intake.

Can't wait to see how yours turns out. I think I might go with the same set up as you for materials as Carbon Fibre is fairly expensive and I don't want to use it on my first try. Is the resin you are using easy to find?

Posted: Mon Oct 31, 2005 3:46 pm

by Kohburn

Oversteer wrote:Must be nice having the skills and the equipment to do things like this. For me, most of my skills are focused around the work I do, but with consulting you spend so much time talking a planning things, that actually getting down and doing them is a whole different ball game. Your project has given me the courage to actually start my project.

I decided to start with a short runner intake, and see how that goes, if it works out, I can modify the intake I am making to accept the longer runners with the runner control modules I got off the SHO intake.

Can't wait to see how yours turns out. I think I might go with the same set up as you for materials as Carbon Fibre is fairly expensive and I don't want to use it on my first try. Is the resin you are using easy to find?

skills are just from having the gonads to go out and learn stuff with a little ingenuity thrown in there

equipment can all be purchased or made

the resin is readily available to anyone with internet or telephone -

Posted: Mon Oct 31, 2005 3:49 pm

by Oversteer

Can you give me the contact info you have?