FUUUUUUUCCCKKK! Part 2: Death --> All.

Moderator: ericjon262

-

Blue Shift

- Posts: 1062

- Joined: Wed Jun 29, 2005 2:28 am

- Location: Los Angeles, CA

FUUUUUUUCCCKKK! Part 2: Death --> All.

I'm sure you guys are familiar with the saga of the 383 powered Cobalt trihull skiboat. Well, yesterday my buddy brought his jetski out and I took out the boat since God decided that it's not really mid January right now. Let's just say that it was a wierd, wierd day when it came to luck, during which:

- The jetski refused to start, then refused to start with a fresh battery - siezed.

- The other jetski refused to start, then changed its mind, started, and promptly crashed into the boat.

- We ran the boat and jetski side by side and were dead even (win!)

- We towed a couple of duck hunters that were broken down in the channel

- The duck hunters towed us when the engine blew up 50 feet from the launch ramp (WTF!)

- We waited while yet another dude struggled with a failed outdrive on his boat

- We all helped after this dudes dog stepped on the "lock" button and locked him out of his van, while it was running.

- We all helped this dude when his van couldn't pull his boat back up the ramp and almost went into the drink

http://vids.myspace.com/index.cfm?fusea ... d=50573394

So yeah. This would be worthy of Failblog if I had all the not so fine points of the day on video.

- The jetski refused to start, then refused to start with a fresh battery - siezed.

- The other jetski refused to start, then changed its mind, started, and promptly crashed into the boat.

- We ran the boat and jetski side by side and were dead even (win!)

- We towed a couple of duck hunters that were broken down in the channel

- The duck hunters towed us when the engine blew up 50 feet from the launch ramp (WTF!)

- We waited while yet another dude struggled with a failed outdrive on his boat

- We all helped after this dudes dog stepped on the "lock" button and locked him out of his van, while it was running.

- We all helped this dude when his van couldn't pull his boat back up the ramp and almost went into the drink

http://vids.myspace.com/index.cfm?fusea ... d=50573394

So yeah. This would be worthy of Failblog if I had all the not so fine points of the day on video.

-

Blue Shift

- Posts: 1062

- Joined: Wed Jun 29, 2005 2:28 am

- Location: Los Angeles, CA

Anyways, the motor barely has over 10 hours on it, and the new jet drive must have ~5.

We were towing the duck hunters back to the docks at just off idle, ~2000 RPM when the noise happened. It was a loud, tinny, "CLACK CLACK CLACK CLACK" at camshaft speed, indicating something wrong with the valvetrain. A couple people agreed that it sounded like something whacking the valve cover, as opposed to the deeper, lower frequency "clock clock" of rodknock. It only clacked a few times before I got I got it shut down.

I'm not sure what it is yet (I'm going to go outside and open it up to look), but I suspect a couple things - Maybe a valvespring broke, or the retainers got free and the valve dropped. Another possibility is that the pushrod or rocker got free and the cam is tossing the pushrod up into the valve cover. Since it happened at very low RPM, I'm hoping that no serious damage was done, though if the valve got bent, it could have fucked up the piston, cylinder, and chamber and all that. Let us hope for the best.

But holy shit. I don't believe in curses, but I'm starting to. I know my skills and abilities are plenty sufficient to get the job done right, but I begin to wonder about even that sometimes. Update on what I find when I open it up.

We were towing the duck hunters back to the docks at just off idle, ~2000 RPM when the noise happened. It was a loud, tinny, "CLACK CLACK CLACK CLACK" at camshaft speed, indicating something wrong with the valvetrain. A couple people agreed that it sounded like something whacking the valve cover, as opposed to the deeper, lower frequency "clock clock" of rodknock. It only clacked a few times before I got I got it shut down.

I'm not sure what it is yet (I'm going to go outside and open it up to look), but I suspect a couple things - Maybe a valvespring broke, or the retainers got free and the valve dropped. Another possibility is that the pushrod or rocker got free and the cam is tossing the pushrod up into the valve cover. Since it happened at very low RPM, I'm hoping that no serious damage was done, though if the valve got bent, it could have fucked up the piston, cylinder, and chamber and all that. Let us hope for the best.

But holy shit. I don't believe in curses, but I'm starting to. I know my skills and abilities are plenty sufficient to get the job done right, but I begin to wonder about even that sometimes. Update on what I find when I open it up.

-

Boscolingus

- Posts: 448

- Joined: Sat Dec 16, 2006 8:38 pm

- Location: Valencia, CA

You found this out by trial and error I'm guessing?lowlux wrote:i should point out that brothers and sister should never fuck...

Damn Chris, you've got to be kidding! That seriously sucks dude. That's like 2-3 engines int he boat, and 2 in the Fiero now? Yikes man. You need to change something in your builds. You're using quality parts, so it's got to be either machine, or assembly related. If I were in your shoes, I'd buy a SBC crate engine from Edelbrock or somewhere. Warranty, and machining/assembly you can trust. You may spend a few hundred more, but it'd be cheaper and easier in the long run. It is no longer cost effective to build your own SBC anymore.

88GT 3.4 DOHC Turbo

Gooch wrote:Way to go douche. You are like a one-man, fiero-destroying machine.

-

Blue Shift

- Posts: 1062

- Joined: Wed Jun 29, 2005 2:28 am

- Location: Los Angeles, CA

Blue Shift, shitty deal man!

By now you have learned 2 important facts about boating.

First is that shit can and will break, and break on a regular basis with old boats.

Second is that boaters are a different breed, a good kind, there's no discrimination amongst boaters, boaters will always go out of their way to help other boaters.

There's good and bad in your list of events, they seem to go hand in hand, thankfully we boaters have the second thing I listed.

Your story sounds like my fathers last 2 seasons of boating, he was either helping someone else, a stranger even, or they were helping him ashore.

Boats are money pits no doubt, but it's something most boaters take in stride.

I sold my boat in 06, I miss the independance of going boating when I wanted, but I don't miss the upkeep associated with it.

Good luck man!

By now you have learned 2 important facts about boating.

First is that shit can and will break, and break on a regular basis with old boats.

Second is that boaters are a different breed, a good kind, there's no discrimination amongst boaters, boaters will always go out of their way to help other boaters.

There's good and bad in your list of events, they seem to go hand in hand, thankfully we boaters have the second thing I listed.

Your story sounds like my fathers last 2 seasons of boating, he was either helping someone else, a stranger even, or they were helping him ashore.

Boats are money pits no doubt, but it's something most boaters take in stride.

I sold my boat in 06, I miss the independance of going boating when I wanted, but I don't miss the upkeep associated with it.

Good luck man!

-

Blue Shift

- Posts: 1062

- Joined: Wed Jun 29, 2005 2:28 am

- Location: Los Angeles, CA

yeah, we went from fastest boat on the water that day, to being towed by a rowboat. Story of my life. :la: Boaters are a pretty cool group - I've done my share of towing and being towed.

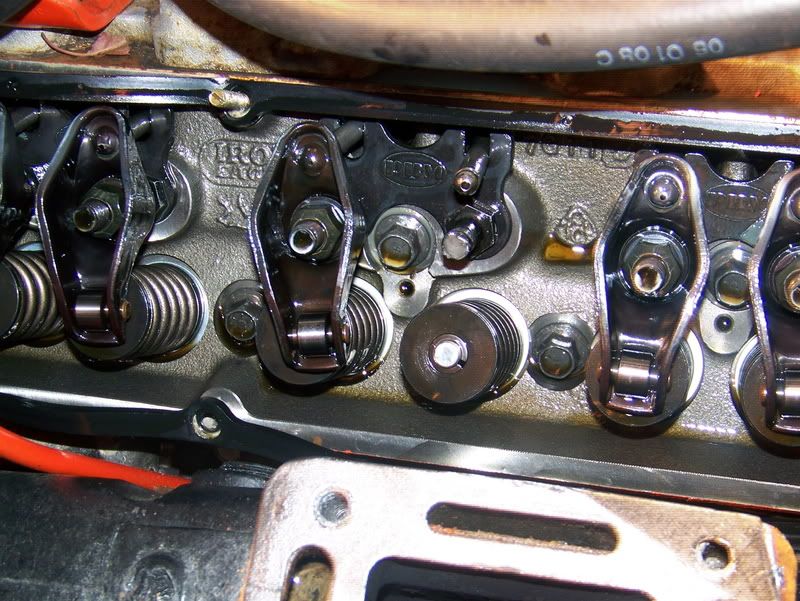

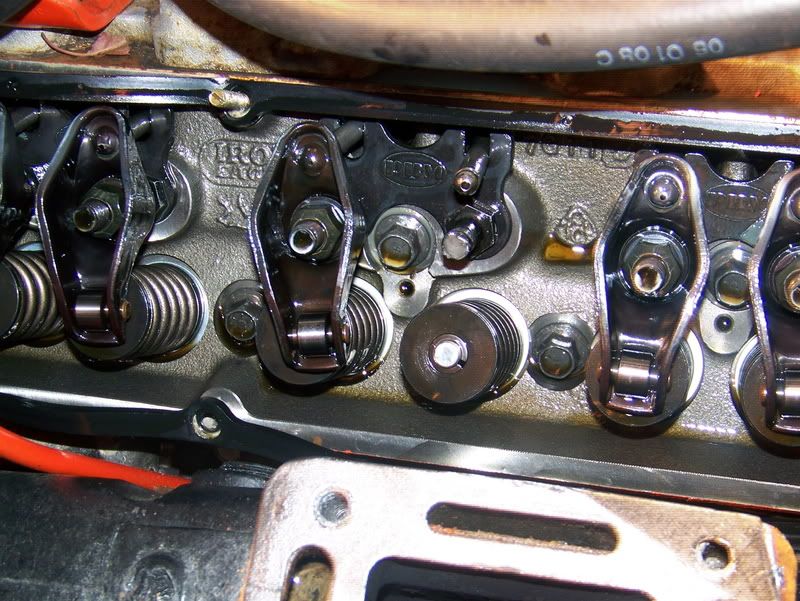

Anyways I took a look at the motor... I pulled the valve cover to find this:

Looks like a rocker stud broke clean off and the rocker arm just fell right off. The noise was the pushrod banging into the valve cover... Good news.

The other valve cover had milky oil spray on it - that's right above where a drainback passage is in the head. It's possible that the water vapor from blowby condensed there, or that the oil is full of water.

This is the part that concerns me. Though hard to see in the blurry picture, the dipstick is broken off on the last inch! It comes into the engine at the middle main, between bobweights on the crank. There appears to be a shiny mark at the break, as though it were mashed off.

This is plugs 2 4 6 and 8 from L to R. I believe 6 is the cylinder that lost the rocker. 8 isn't looking too healthy.

I dunno what it all means. I could be ok, but I'm thinking I'm going to see some pissed off parts when I pull the pan off tomorrow.[/img]

Anyways I took a look at the motor... I pulled the valve cover to find this:

Looks like a rocker stud broke clean off and the rocker arm just fell right off. The noise was the pushrod banging into the valve cover... Good news.

The other valve cover had milky oil spray on it - that's right above where a drainback passage is in the head. It's possible that the water vapor from blowby condensed there, or that the oil is full of water.

This is the part that concerns me. Though hard to see in the blurry picture, the dipstick is broken off on the last inch! It comes into the engine at the middle main, between bobweights on the crank. There appears to be a shiny mark at the break, as though it were mashed off.

This is plugs 2 4 6 and 8 from L to R. I believe 6 is the cylinder that lost the rocker. 8 isn't looking too healthy.

I dunno what it all means. I could be ok, but I'm thinking I'm going to see some pissed off parts when I pull the pan off tomorrow.[/img]

-

p8ntman442

- cant get enough of this site!

- Posts: 3289

- Joined: Wed Mar 30, 2005 2:37 pm

- Series8217

- 1988 Fiero Track Car

- Posts: 5989

- Joined: Thu Jun 02, 2005 9:47 pm

- Location: Los Angeles, CA

There are beachmarks on the rocker stud where it broke. It was slow crack propogation. Cheap studs I think.

I don't know what the deal with the wet plug is, but I wouldn't worry about it since if its a problem you can't do anything about it without disassembly. The motor seems to be running great yeah? 51 mph with the trim still at zero -- that kicks ass with a trihull family cruiser!

I would pull the pan to see about extending the dipstick tube so it doesnt break again... orrrr just leave the new dipstick out when you aren't checking the oil.

I don't know what the deal with the wet plug is, but I wouldn't worry about it since if its a problem you can't do anything about it without disassembly. The motor seems to be running great yeah? 51 mph with the trim still at zero -- that kicks ass with a trihull family cruiser!

I would pull the pan to see about extending the dipstick tube so it doesnt break again... orrrr just leave the new dipstick out when you aren't checking the oil.

-

Atilla the Fun

- Posts: 2446

- Joined: Mon Jan 07, 2008 1:36 pm

-

Blue Shift

- Posts: 1062

- Joined: Wed Jun 29, 2005 2:28 am

- Location: Los Angeles, CA

On closer examination, the stud clearly failed over a long time due to the spread of a crack. The "beach marks" show the progressive spread of the crack from a flaw, until it snapped right off.

So I just got done doing a leakdown test. Far as I can tell it shows that all cylinders are actually there, and it seems pretty even over the length of each cyl. Scary thing, is that there seems to be a minor increase in leakage on Cyl 8, which is the one with dark/wet plug, while the others all appear to be white/tan like normal. I took a look at the old pics and it's not the cylinder with a repaired head bolt hole. Not sure what's going on, but I wonder if water is finding its way in? Might end up having ot pull the heads to look.

Provided nothing super expensive is broken, I'm going to ARP studs (~30 bucks) and full roller rockers. I like the idea of the Comp Pro Magnum rockers - they're fully chrome moly steel, yet lighter than aluminum at the valve. It should be brutally strong, and free up a few HP due to friction.

Atilla - do you know of any failure modes that involve the rear cylinders? #7 looks to have had a rusty color on the insulator too. I'm beginning to think water is getting in somewhere.

So I just got done doing a leakdown test. Far as I can tell it shows that all cylinders are actually there, and it seems pretty even over the length of each cyl. Scary thing, is that there seems to be a minor increase in leakage on Cyl 8, which is the one with dark/wet plug, while the others all appear to be white/tan like normal. I took a look at the old pics and it's not the cylinder with a repaired head bolt hole. Not sure what's going on, but I wonder if water is finding its way in? Might end up having ot pull the heads to look.

Provided nothing super expensive is broken, I'm going to ARP studs (~30 bucks) and full roller rockers. I like the idea of the Comp Pro Magnum rockers - they're fully chrome moly steel, yet lighter than aluminum at the valve. It should be brutally strong, and free up a few HP due to friction.

Atilla - do you know of any failure modes that involve the rear cylinders? #7 looks to have had a rusty color on the insulator too. I'm beginning to think water is getting in somewhere.

-

Atilla the Fun

- Posts: 2446

- Joined: Mon Jan 07, 2008 1:36 pm

Re: FUUUUUUUCCCKKK! Part 2: Death --> All.

The rear cyl's tend to run the hottest, I usually hone them a half thou. extra, but this is more about wear and friction. If your top rings got too hot and the ends butted, this coulda damaged something, but your compression test should show it. My own experiences with Dart heads is the guides get barrel-shaped fast, so if you do pull your heads, check that. Also, in a car, the rear cylinders are normally slightly lower to the ground than the front, like when you're up on a plane, so the oil is more likely to get past those guides. I only use fully-rubber valve seals with the metal bands arount them.

Did you have the heads lightly milled flat before installation? Most out-of-the-box heads tend to distort a bit by the time you get them, because the machining is done before the heads are cooled from the casting molds. I've found they generally need resurfacing to be flat.

You could be getting coolat in that cylinder from either a head or intake gasket leak, or a flaw in the block. Dart uses a truly dense iron, so I wouldn't suspect head porousity.

Did you have the heads lightly milled flat before installation? Most out-of-the-box heads tend to distort a bit by the time you get them, because the machining is done before the heads are cooled from the casting molds. I've found they generally need resurfacing to be flat.

You could be getting coolat in that cylinder from either a head or intake gasket leak, or a flaw in the block. Dart uses a truly dense iron, so I wouldn't suspect head porousity.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15629

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: FUUUUUUUCCCKKK! Part 2: Death --> All.

Doesn't his intake have coolant ports at all four corners of the engine?Atilla the Fun wrote:The rear cyl's tend to run the hottest, I usually hone them a half thou. extra, but this is more about wear and friction.

-

Blue Shift

- Posts: 1062

- Joined: Wed Jun 29, 2005 2:28 am

- Location: Los Angeles, CA

Re: FUUUUUUUCCCKKK! Part 2: Death --> All.

Well, I got some ARP studs, stainless roller rockers, and Crane pushrods to replace broken parts and finally got em installed today. Here's a video from startup, with the valve covers off so I could see any problems:

http://www.youtube.com/watch?v=wYWfEFKb09M

Since the risers weren't bolted on, there were blue fireballs coming out every time it loped, so I got a short video of it - pretty cool:

http://www.youtube.com/watch?v=orOK0Eqp0-k

So, all's well that ends well, right? With the valve covers off, I spotted some bubbles coming up from a couple of the headbolts, and from one valve spring seat - scary. Atilla, you ever see anything like this? I used that gooey permatex teflon paste on all my head bolts, but I suppose maybe water could be leaking past anyways, especially when it's being rammed into the engine by the jet pump. Maybe it's boiling and unable to leak back past the threads fast enough, it comes up out of the underside of the bolt head? But for the bubbles coming from the valve spring seat, I have no idea, unless maybe it's water condensation that puddled under the spring and was boiling off?

Headbolts: http://www.youtube.com/watch?v=CtjIV8lE1m0

Spring Seat: http://www.youtube.com/watch?v=vzKu6js2XyE

WTF M8? I figure I'll run it again tomorrow on the hose and let it get to operating temp and see if it bubbles still - maybe it's condensation boiling off. I also wonder if I warped the heads when it overheated back when I was breaking it in at the launchramp? We had a cooling flow problem with the new exhaust I didn't catch until the engine was quite hot. These heads are insanely thick and heavy castings, but you never know. Maybe they needed a skim, like mentioned above.

Any ideas?

http://www.youtube.com/watch?v=wYWfEFKb09M

Since the risers weren't bolted on, there were blue fireballs coming out every time it loped, so I got a short video of it - pretty cool:

http://www.youtube.com/watch?v=orOK0Eqp0-k

So, all's well that ends well, right? With the valve covers off, I spotted some bubbles coming up from a couple of the headbolts, and from one valve spring seat - scary. Atilla, you ever see anything like this? I used that gooey permatex teflon paste on all my head bolts, but I suppose maybe water could be leaking past anyways, especially when it's being rammed into the engine by the jet pump. Maybe it's boiling and unable to leak back past the threads fast enough, it comes up out of the underside of the bolt head? But for the bubbles coming from the valve spring seat, I have no idea, unless maybe it's water condensation that puddled under the spring and was boiling off?

Headbolts: http://www.youtube.com/watch?v=CtjIV8lE1m0

Spring Seat: http://www.youtube.com/watch?v=vzKu6js2XyE

WTF M8? I figure I'll run it again tomorrow on the hose and let it get to operating temp and see if it bubbles still - maybe it's condensation boiling off. I also wonder if I warped the heads when it overheated back when I was breaking it in at the launchramp? We had a cooling flow problem with the new exhaust I didn't catch until the engine was quite hot. These heads are insanely thick and heavy castings, but you never know. Maybe they needed a skim, like mentioned above.

Any ideas?

-

Atilla the Fun

- Posts: 2446

- Joined: Mon Jan 07, 2008 1:36 pm

Re: FUUUUUUUCCCKKK! Part 2: Death --> All.

I just watched your 2 videos. Overheating can actually do more damage to heads that are more rigid. Those darts are great for withstanding boost and detonation, but if this was my engine, I would pull the heads, and find a machine shop that can pressurize the coolant passages with air. It can be difficult to magnaflux in the bolt passages. Also, I'd straightedge them to see if they needed a slight shave. But if you'd rather work with them on, I'd say get some rifle brushes to clean out the sealant you used, then remove the bolts that are leaking, clean, and reassemble with a better sealing product. I wouldn't worry too much about retorquing in the prescribed pattern if it's just 2 bolts.

As for the spring seat, while you can hold the valves shut with compressed air, in this instance I'd recommend the method of feeding string through the spark plug hole. No telling what you'll find, if anything, when you remove the spring, and you'd kill any air compressor if you have to keep the spring off for more than a couple of hours.

If you're not getting any coolant in the cylinders, then just pull the spring, and have a machinist bring his magnafluxing stuff. You need to wipe away all the oil, and use something like carb cleaner or brake cleaner. Spray your clean rag, not the head. It must be perfectly clean and dry for magnafluxing, and he will need access to 120 volt alternating current, and extension cords, if required, need to be ready before he gets there.

If the spring seat is cracked, I'd call Dart directly.

Was this just one head, not both?

As for the spring seat, while you can hold the valves shut with compressed air, in this instance I'd recommend the method of feeding string through the spark plug hole. No telling what you'll find, if anything, when you remove the spring, and you'd kill any air compressor if you have to keep the spring off for more than a couple of hours.

If you're not getting any coolant in the cylinders, then just pull the spring, and have a machinist bring his magnafluxing stuff. You need to wipe away all the oil, and use something like carb cleaner or brake cleaner. Spray your clean rag, not the head. It must be perfectly clean and dry for magnafluxing, and he will need access to 120 volt alternating current, and extension cords, if required, need to be ready before he gets there.

If the spring seat is cracked, I'd call Dart directly.

Was this just one head, not both?