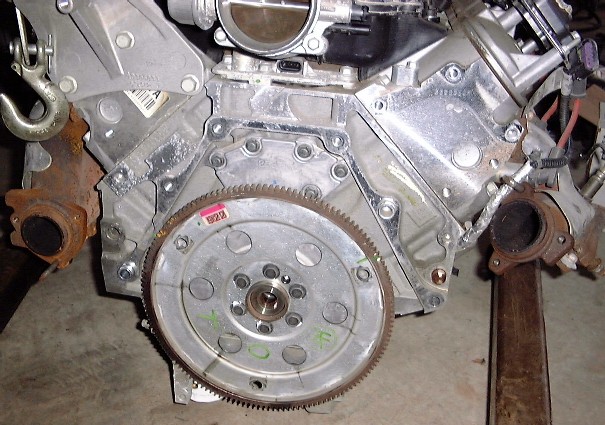

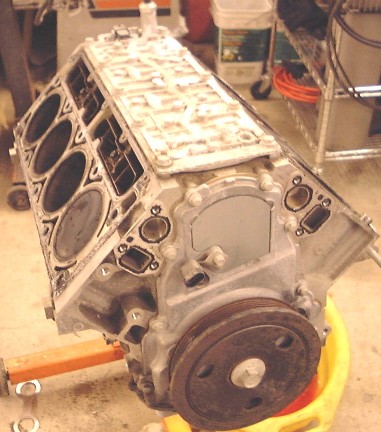

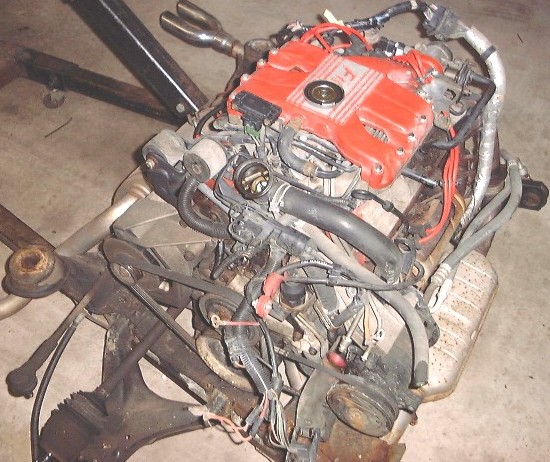

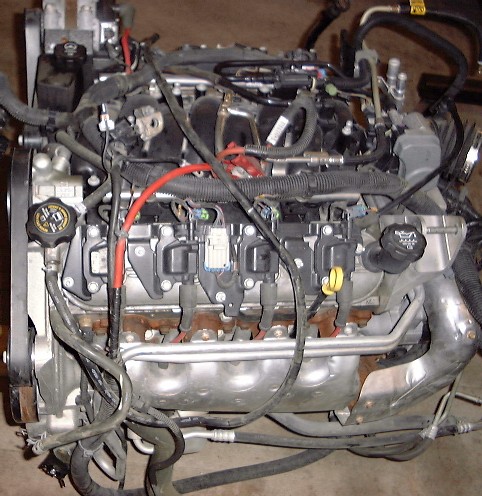

Donor motor, transmission, and related parts came out of a 2005 Grand Prix GXP courtesy of Ed Morad Parts Co. http://www.moradpartscompany.com

All of this will be going into a 1987 Fiero GT. The features that are planned to be included in the swap are:

-The transmission TAPShift function (steering wheel mounted shift paddles)

-DoD (displacement on demand) function in the engine

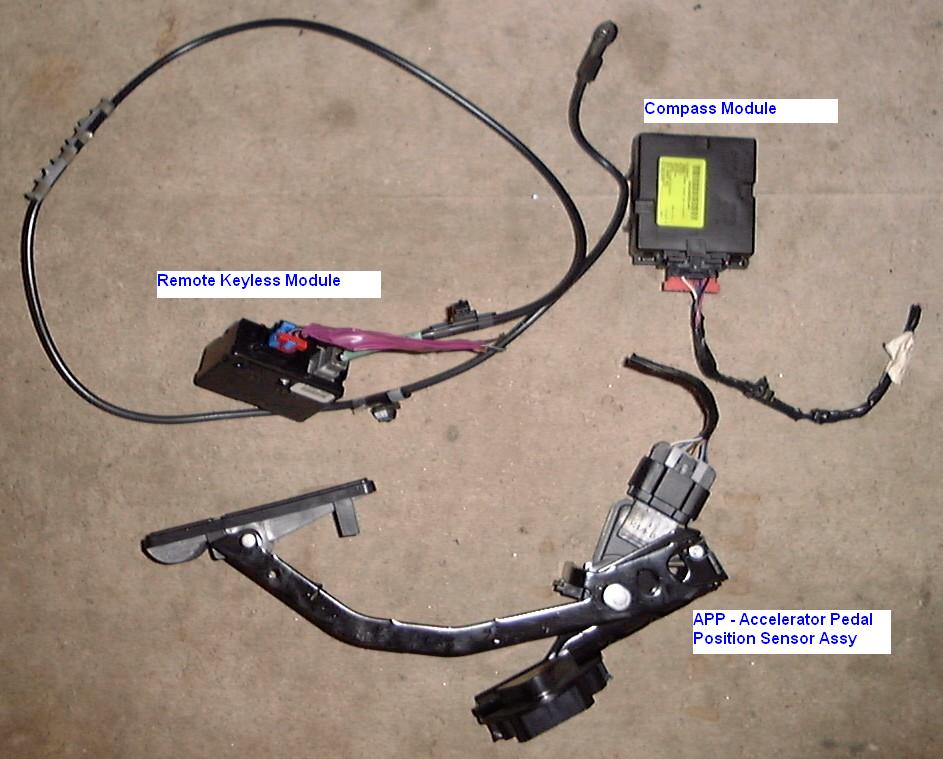

-And factory remote start / keyless entry / driver info center.

THE PLAN:

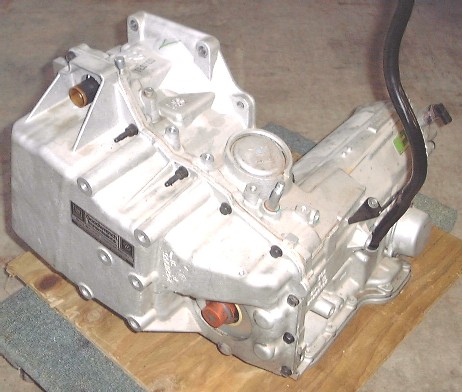

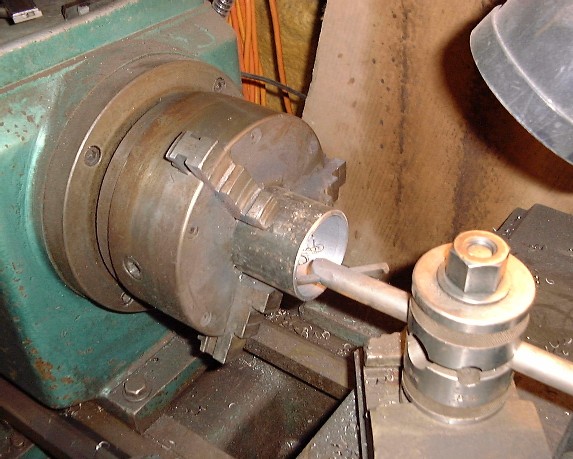

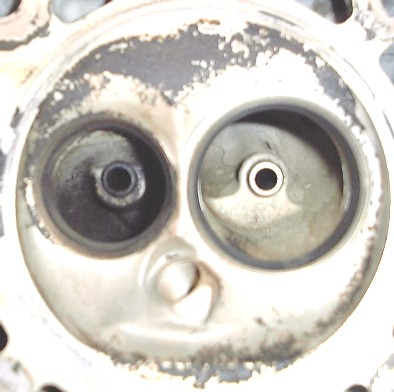

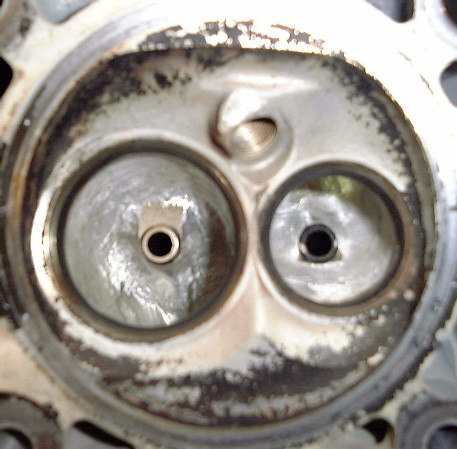

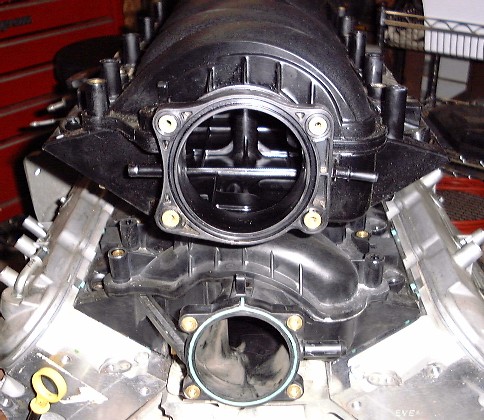

Phase 1 has been completed which was to port the cylinder heads in order to increase power output of the engine without sacrificing drivability or fuel economy. An aftermarket cam was considered as on option but no suitable affordable unit was available. Also the transmission has been gone thru (by TripleEdgePerformance: http://www.tripleedgeperformance.com ) in order to install a shift improver kit and various fixes for known bugs.

Phase 2 is the mechanical and electrical aspects of the engine/transmission swap. The plan is to complete this phase and get the engine running before I move on to Phase 3.

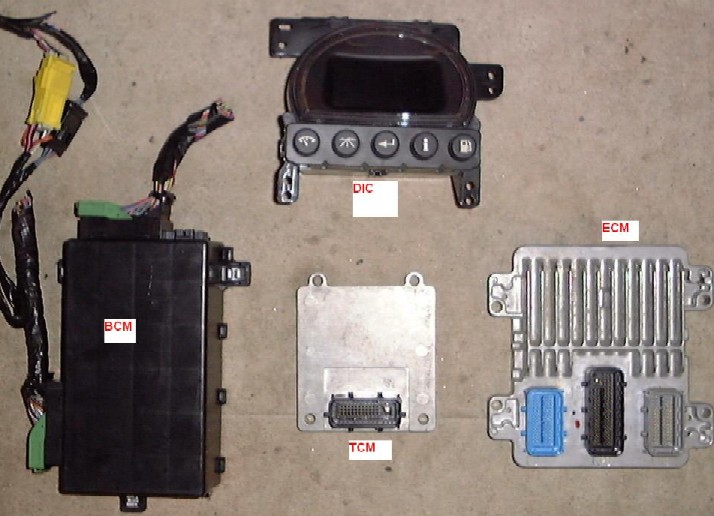

Phase 3 is to install the BCM, DIC, and other modules we got from the Grand Prix in to the Fiero to see how much of it I can get working without too much trouble. There is currently no programming software available that can reprogram the BCM to remove certain functions so I imagine I will have a lot of work to do in order to "fool" certain inputs and outputs in order to prevent warning messages from being displayed on the DIC.

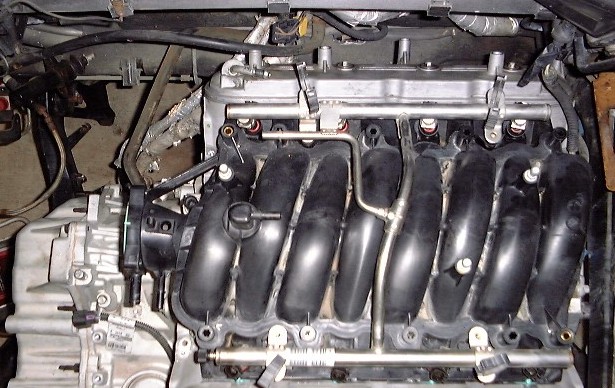

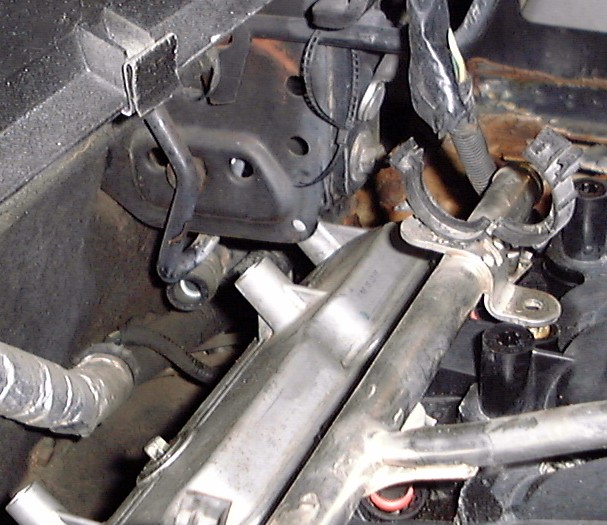

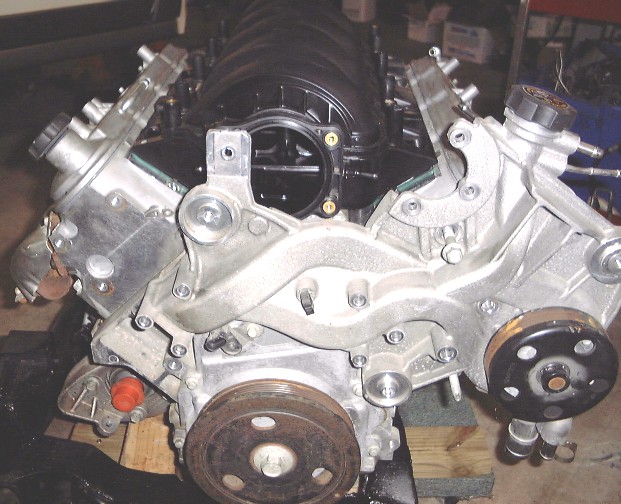

A couple of things I have noticed about this engine is it shares a lot of the standard architecture with the LS1 series of engines, except for the bellhousing bolt pattern, starter mounting location, shorter crank, and more compact assy/belt drive setup. The transmission is actually going to create some issues because GM didn't cast in extra support in the area of the left rear mount -- probably because it wasn't used in the Grand Prix. I already have an idea of how to work around this issue so I can use my 4-corner mount system that doesn't require a dog-bone. Stock this powertrain only used 3 lower mounts (two on the pass side and one on the driver's side), which would require the use of a dog bone on the driver's side -- where no such provisions exist on the Fiero chassis. One of the goals I have for this swap is to modify the Fiero chassis as little as possible (if at all).

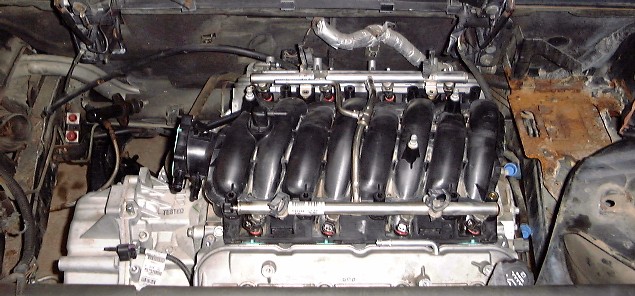

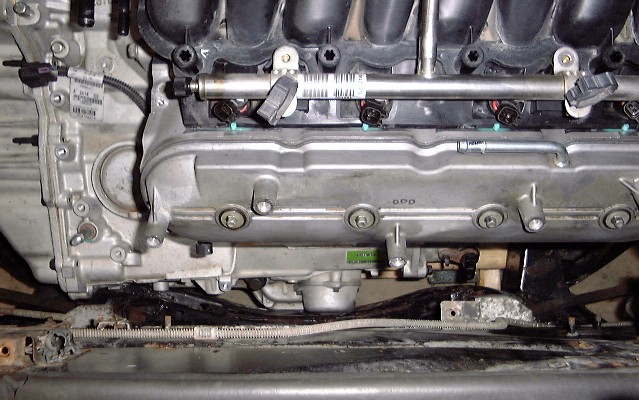

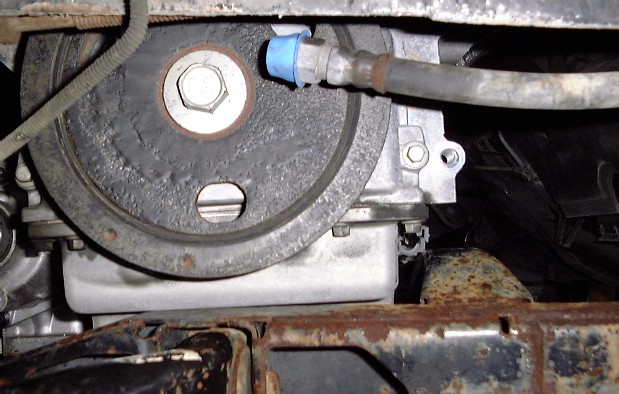

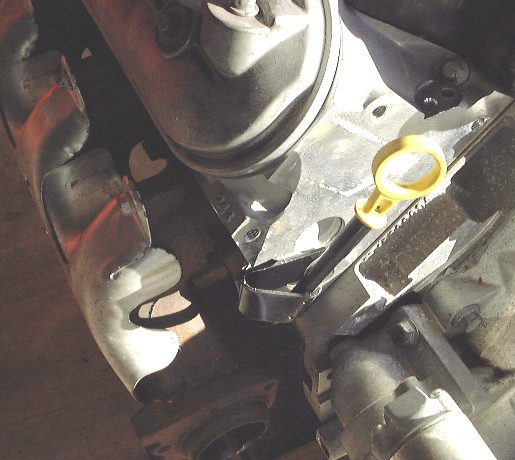

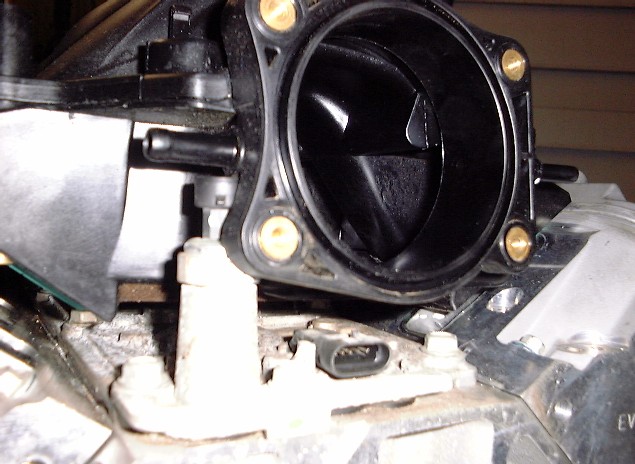

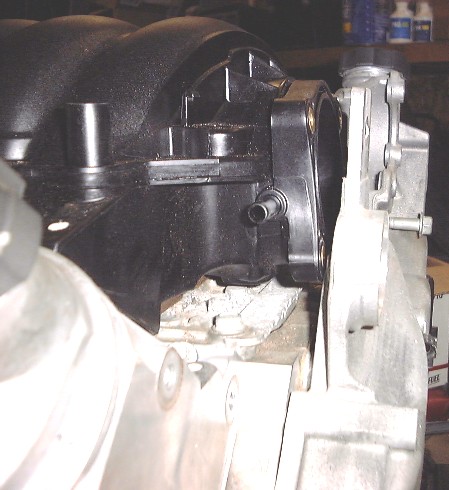

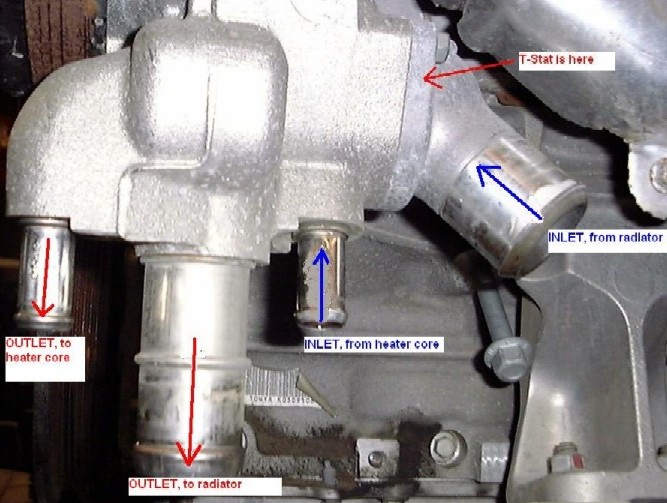

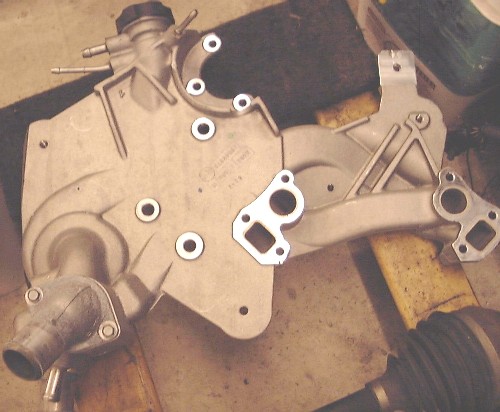

The front cover / water pump housing used on this engine is quite ingenious. All coolant connections are located in this cover as well as the fill point for the entire cooling system (the grand prix's radiator did not have a fill point on it). Below is a picture of the T-stat housing and all heater hose and radiator hose connections, which are located just behind and below the water pump.

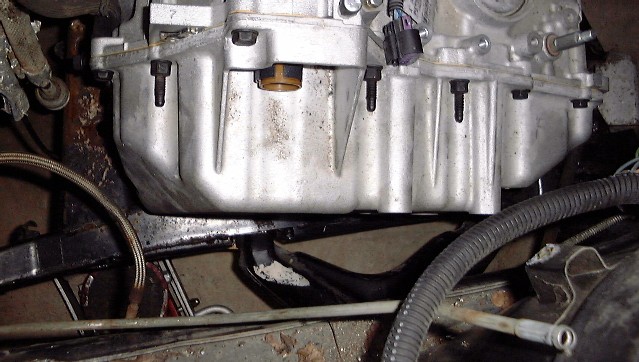

On this engine the starter is mounted to the transmission which is unique. The transmission case has a special casting to accomodate this.

More pictures to follow. Other pictures and information on the LS4/4T65-E can be found on a page I dedicated to this powertrain on my website here:

http://www.gmtuners.com/LS4/index.htm

-ryan